HART (Highway Addressable Remote Transducer)

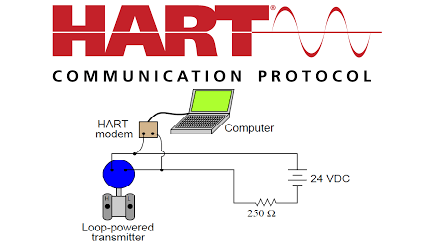

HART is a protocol that operates on a combination of analog and digital signals to facilitate communication between a master device (e.g., controller) and field instruments (e.g., sensors or actuators). Here’s a concise explanation of how HART works:

- Analog Signal Transmission: The primary process variable, such as temperature or pressure, is transmitted as a 4-20 mA analog signal over the same wires that provide power to the field device. This analog signal represents the real-time measurement.

- Digital Signal Overlay: HART overlays a digital signal on top of the analog signal. This digital signal carries additional information, such as device diagnostics, configuration parameters, and other relevant data.

- Master-Slave Communication: In a HART network, there is a master device (e.g., a controller or PLC) and one or more slave devices (field instruments). The master communicates with each slave device individually in a polling manner.

- Addressable Communication: Each HART device has a unique address. The master sends a command with the desired device address, and the corresponding field device responds with the requested information.

- Bi-Directional Communication: HART supports bidirectional communication, allowing the master to not only request data but also configure and command the field devices remotely. This capability is valuable for device setup, calibration, and troubleshooting.

- Device Description Language (DDL): HART uses Device Description Language to define and standardize the communication protocol for each type of field device. This ensures interoperability and provides a common framework for understanding device capabilities.

From an economic standpoint, HART is cost-effective as it allows the use of existing 4-20 mA wiring infrastructure for digital communication, eliminating the need for additional cabling. On the technical side, HART provides enhanced functionality, diagnostics, and remote management, contributing to improved efficiency and maintenance in industrial processes.

Discover more from Susiloharjo

Subscribe to get the latest posts sent to your email.